Veneering Workshop - Making and Using Shop-Sawn Veneers

Veneering Workshop - Making and Using Shop-Sawn Veneers

Making and Using Shop-Sawn Veneers

Instructor Craig Stevens

to be scheduled again

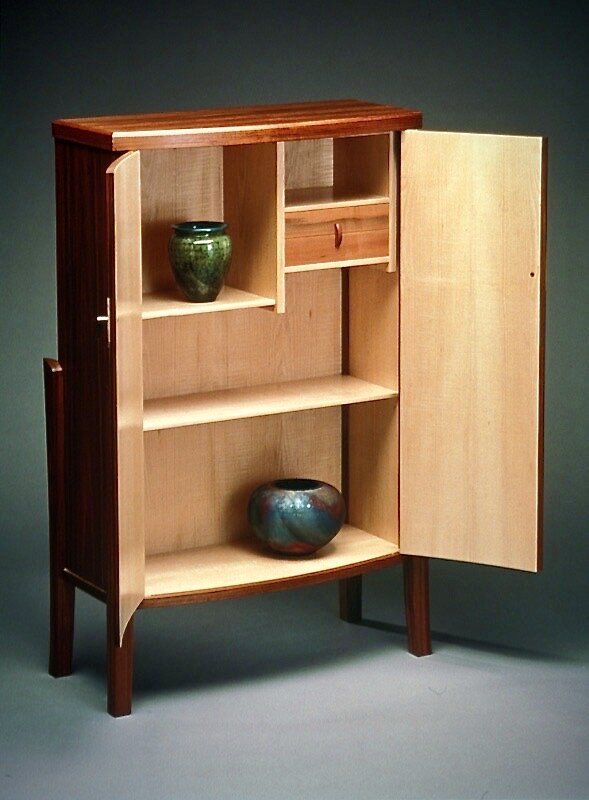

The versatile techniques associated with veneering have a rich history and can expand the furniture maker’s ability to design and make beautiful, creative furniture. Hand-sawn veneers offer stability and design freedom as well as providing surfaces that are thick enough at about 1/16” to be worked with hand planes or sanded without fear of sanding through.

Equally important, slicing a solid plank into relatively thick veneers dramatically stretches the material, covering a much larger surface with beautiful or rare wood than would be possible with solid wood construction.

Participants will be guided through the process of making and using high-quality shop-sawn veneers including lumber selection, bandsaw set up & trouble-shooting, sawing and edge-joining veneers, and glue-up techniques using a vacuum press. Solid edge-banding techniques complete the veneering process. Choosing adhesives, a variety of core materials, and creating curved panels will also be discussed.

Each student will create a small, veneered panel which could serve as a tabletop or simply a reminder of the techniques involved in the process. Hands-on assistance, aimed at improving participants design and woodworking skills is the focal point of the workshop.

Cost includes all materials. Students provide their own lunch.

Continue scrolling down for Tool List

PFW has a wide assortment of tools for students to use. However, if you have your own tools or would like an excuse to purchase some new ones, the tool list is below. PFW recommends purchasing tools from Tools for Working Wood, Lee Valley/Veritas, Hida Tool and Hock Tools

Block plane - Lie Nielsen #102 or low angle Lie Nielsen #60 1/2

Hand plane - 9” or longer wooden plane, #4 smoothing plane or #5 jack plane

Small Crosscut saw (western or Japanese) - Gramercy, Lie Nielsen, Lee Valley or Hida Tool Gyokucho #S-372 Japanese dovetail saw

Card scraper

1 roll blue painter’s tape

Small square

Hammer - 10 to 13 oz

Pencil, notebook, safety glasses and hearing protection